Summary

Most of the online stores today offer personalized printed products for their customers. They also provide customers with the freedom to create their own designs with a web-to-print software. Once the design is finalized, it is printed on various products and materials like t-shirts, mugs, mobile skin covers, business cards, etc. For business owners who have integrated web-to-print software into their store, it is important to know about the different printing methods implemented by the web-to-print industry.

For business owners who are just starting out with web to print: How to Create a Web-to-Print E-store Like CustomInk

Here’s a detailed overview of each of the printing methods listed above.

1. Digital Printing

Digital printing is the modern process of printing on different physical surfaces like cloth, magnets, labels, cardboard, plastic, etc., using various techniques like inkjet printing and laser.

The images to be printed are directly sent to the printer using digital files, thus eliminating the need for a printing plate. When using a web to print software, you can create different designs and get a print-ready file that can be directly fed to the printers.

Digital printing is one of the most cost-effective methods that produce high-quality prints.

Also read: Digital Textile Printing + Web-to-Print: A Perfect Blend for your Printing Business

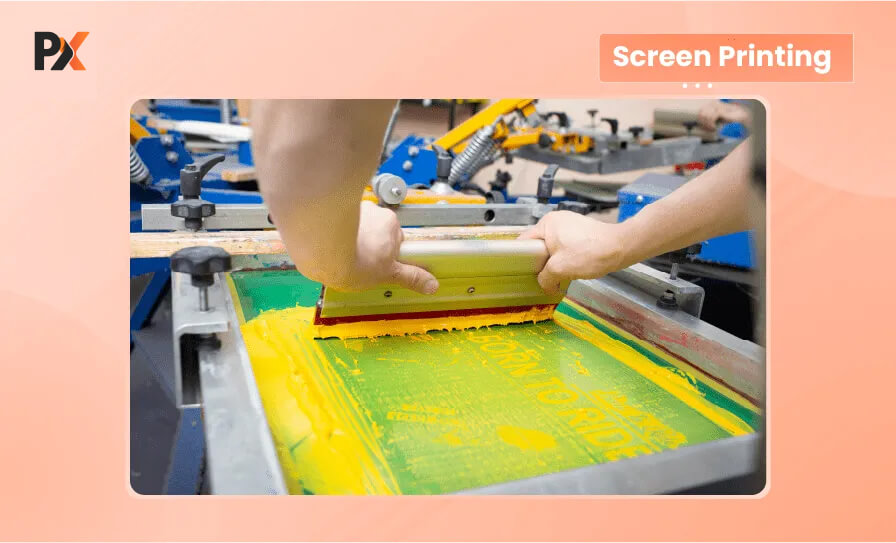

2. Screen Printing

Screen printing utilizes different types of brightly colored inks and is often used for printing posters, t-shirts, and other promotional items.

Initially, screen printing was confined to silk materials. Nowadays, several different types of materials are used.

During the screen printing process, a design is laid on the top of the screen. Thereafter, it is covered with photo emulsion and exposed to light. Due to its exposure to heat, the emulsion hardens up, and the rest of it is washed away, leaving a kind of stencil whose ink can be pulled using a squeegee.

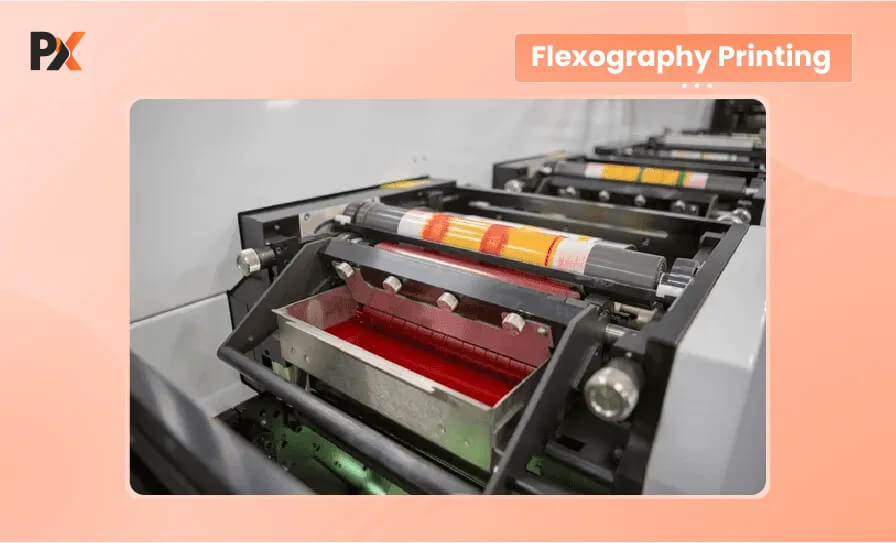

3. Flexography Printing

This kind of printing is usually operated using web presses that print on long and continuous rolls of paper. It doesn’t use standard plates used in offset lithography.

Originally, this method was used for corrugated cardboard with uneven surfaces. The printing plate surface stays in contact with the cardboard because of its flexibility and that is why it is named flexography.

It makes use of water-based inks and rubber plates, which dry very quickly and enable faster production rates. With faster drying, more effective results can be obtained on materials like plastic.

Launch your web-to-print store with us and take your print business to the next level! Start selling personalized products with a fully-functional website in less than 48 hours.

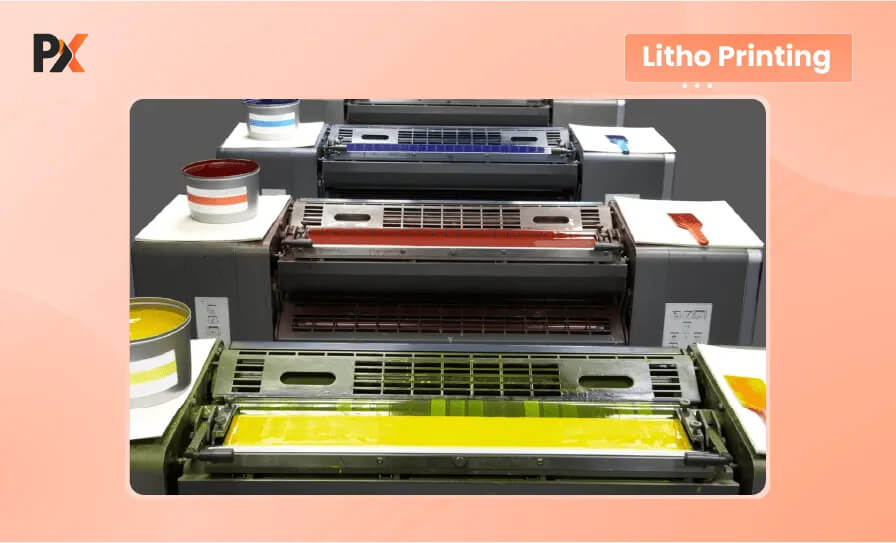

4. Litho Printing

Litho Printing is widely used in mass-production printing. It includes printing plates made of aluminum. Each of the plates will have image content to be printed. Then, the plates are transferred or offset to the roller. The ink on rollers is transferred to paper.

This printing method can produce high-quality images for small and high-volume print jobs.

5. Rotogravure (Gravure) Printing

It is a long-run, high-speed, high-quality printing method. The images produced by this printing method are detailed. The image is engraved on a copper cylinder and uses a rotary printing press.

These presses are the fastest and widest presses in operation. It can print everything from small labels to 12-foot-wide rolls of vinyl flooring.

This printing method is often used for high-volume printing of packaging, gift wraps, and wallpapers.

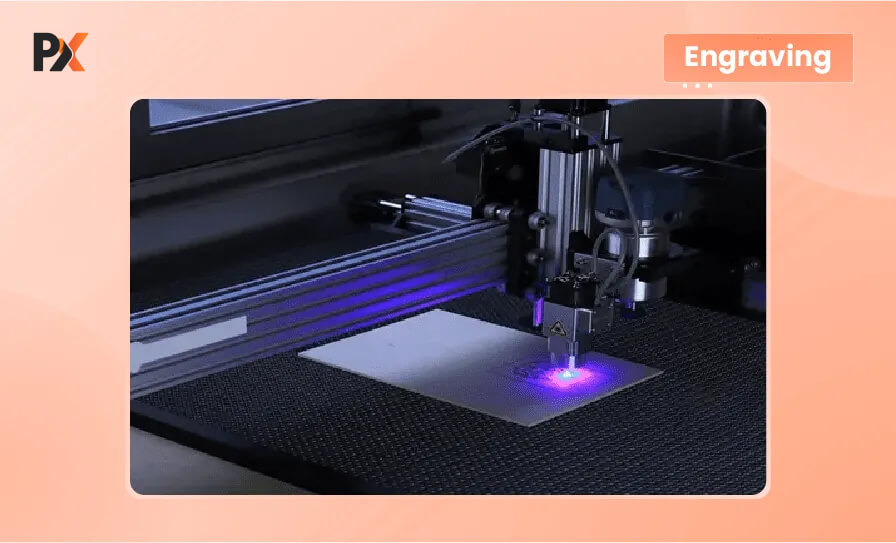

6. Engraving

Engraving is considered to be the most expensive out of all the printing methods. Also, it takes a lot of time to get it implemented.

When it comes to making royal invitation cards or business cards of high-ranking officials, engraving is the most commonly used printing method.

The image is first engraved on a metal plate by a hand or machine. Thereafter, the engraved design is filled in with ink and a paper is pressed on it. As a result, a three-dimensional kind of crisp image can be obtained. Such results are difficult to produce by using other techniques.

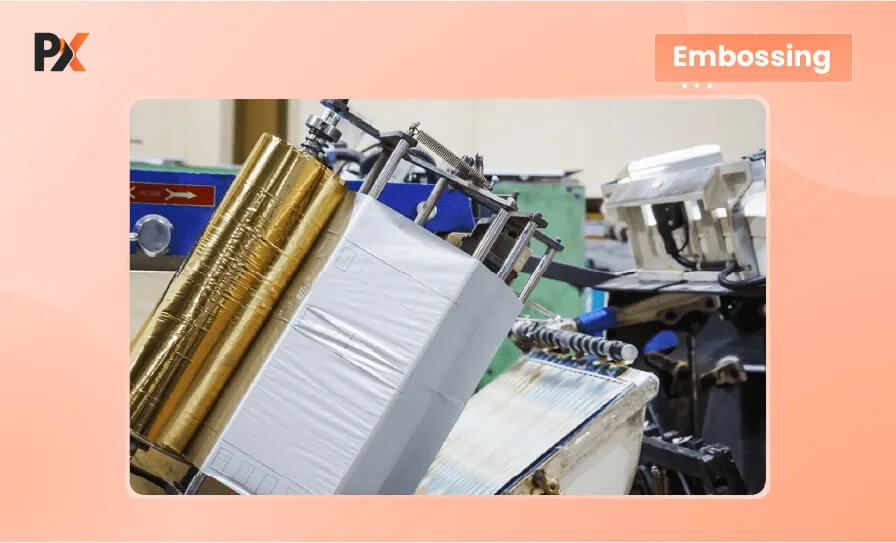

7. Embossing

In this process, an impression of the design is created on a surface of the product. A fixed amount of pressure is given on the objects and marks are left after the pressure is released. There are two types of embossing:

- Blind embossing: The embossed mark is of the colour of the product itself

- Foil block: After the design is embossed, it is filled with metallic paints like silver and gold

8. Embroider Printing

Through embroidery printing, artwork can be recreated by decorating the fabric with designs that are stitched in strands of thread with a needle. A special printing machine is used for bulk production. One can provide color references for this kind of printing. Embroiders try to match the color hues which are nearest to the sample provided. With embroidery printing, it is better if you avoid an amalgamation of different colors.

As the web-to-print industry is widening its horizons, several ways of printing are being adopted by the online store owners. If you have an online store, it’s time you make an investment in web-to-print technology.

You can choose the type of printing that goes the best with your products and offerings. Ecommerce business owners generally prefer a printing solution that is versatile and can enable printing on different types of surfaces. Make sure you invest wisely so there are no embarrassments and regrets at a later stage.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.