Summary

‘Screen printing’ is one of the most popular and centuries old printing methods. Its durability and ability to produce vivid colors, even on darker fabrics, keep it still the number #1 method most commonly for fabric and paper prints.

Sometimes called serigraphy or silk screen printing, screen printing is the process of pressing ink through a stenciled mesh screen to create a printed design. A screen printer transfers a stenciled design onto a flat surface with the help of a mesh screen, ink, and a squeegee.

Apart from fabric and paper prints, screen printing can also be applicable to wood, metal, plastic, and even glass with the help of specialized inks. The basic procedure is to create a stencil on a fine mesh screen first, followed by pushing ink (or paint, in artwork and posters) through to create an imprint of your design on the surface beneath.

Different types of stenciling techniques include:

– Using masking tape or vinyl to cover the desired areas of the screen.

– Painting the stencil onto the mesh using ‘screen blockers’ like glue or lacquer.

– Using a light-sensitive emulsion to create a stencil, developed like a photograph.

Designs made with the screen printing technique can use just one shade of ink or more. In case you use multicolored items, apply colors in individual layers with the help of separate stencils for each ink.

Hence, considering the different types of screen printing, here are its sub types. You can choose the one based on your print requirements:

6 Major Types of Screen Printing

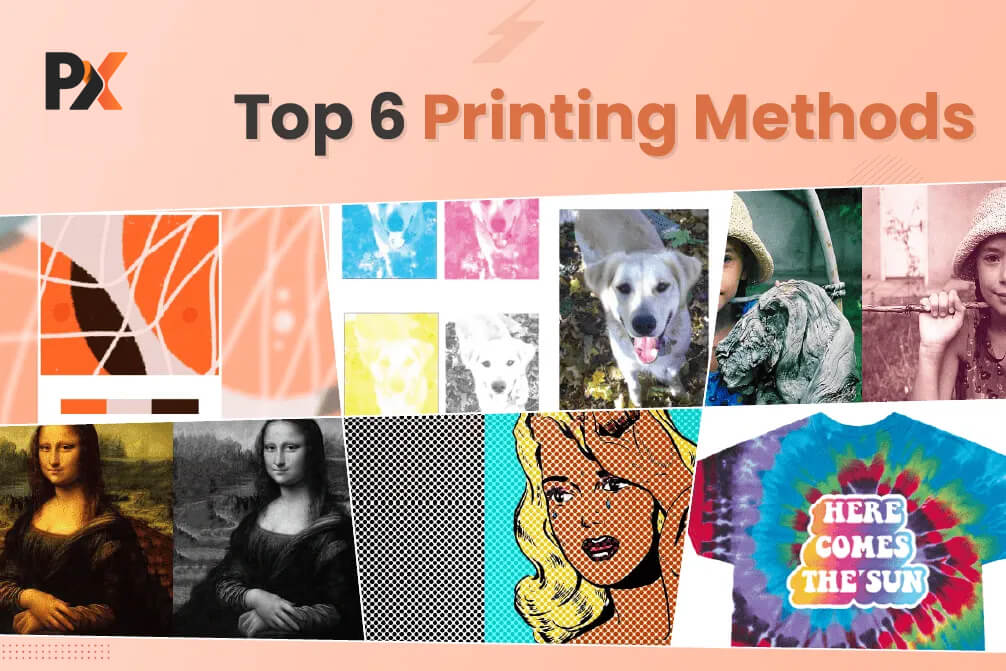

1. Spot Color Screen Printing

Spot Color Screen Printing technique pulls spot colors from several color separation software programs. As a screen printer, you can take these spot colors and print them in solid colors and shapes.

Things to keep in mind:

First, you need to get the art ready and set it for print. You also need to make sure that the design, words, numbers, etc., are up to date for print and that colors are properly separated. If colors are not visibly distinct and separated, or the resolution of the artwork is not high enough, then the final print on the product won’t be as good quality as expected.

So, checking for proper visible separation of colors and high resolution is imperative to ensure good quality output.

Second, a stencil-like tool will transfer the design to the product. Using a stencil helps the product (apparel) absorb the ink properly, and this results in a solid, rich color.

To sum up, spot color screen printing allows for design print to be placed on any type of apparel, and as many spot colors can be used to create the specific image as desired.

Benefits:

– Allows raw, vivid colors to be printed on almost any type of apparel or material.

– Facilitates the maximum control over the colors that help make the final color(s) printed as output look concise, clear, and edged to perfection.

– Simpler to use in comparison to several other screen printing methods as colors are separated instead of being blended in the design itself.

Out of different types of screen printing, Spot Color Screen Printing is one of the most common methods. When it comes to printing on t-shirts, hoodies, and jackets, this method can be an excellent option.

Confused about the equipment you need for screen printing?

Get the list of primary and secondary screen printing equipment you will need for your screen printing business.

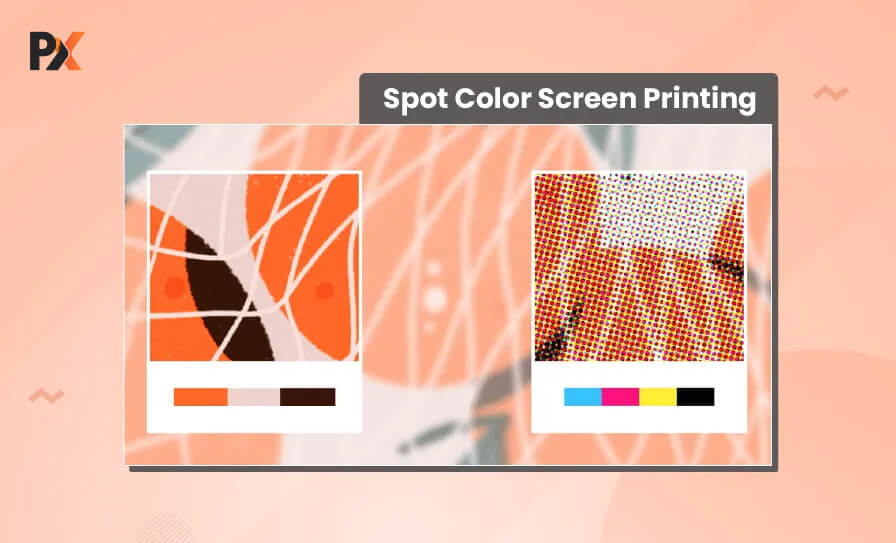

2. Halftone Printing

Halftone printing is a screen printing method that emphasizes the use of shading accompanied by tiny dots. You can use this technique to print pictures – especially monochromatic comprising only one color.

This is because halftone printing looks best when one printed ink color is darker and highlighted more than the background. Actually, the whole process employs only one color of ink, and this color gets half-toned, which results in a seemingly different shade when looked at from a distance.

However, if you look at the artwork closely, you can easily make out that it is only one color that constitutes the entire design. The only difference is – when you print the color in a specific formation of dots rather than in solid form, people have the ‘illusion’ of multiple colors or shades when looking at it from far.

Let’s go through the process now.

First, the screen printer creates the design. Remember – if the image is faulty, the dots from this screen printing method won’t be clear enough for a suitable view. Or you can say a low-resolution image will not appear good in the final print. So, ensure that the resolution of the image is high enough to give the most effective and best results.

Further, a high-mesh count screen is necessary for high-quality output. In layman’s words, it means you shouldn’t place the inked dots on the surface with too much pressure, or they won’t come out right. Getting the inked dots down in the right manner is a crucial step in this process.

Benefits

– Cost-effective as only one color of ink is required. Besides, it is a slightly unique way when compared to other types of screen printing processes as it involves a little bit of only one color to generate ‘apparently’ different shadings.

– Highly recommendable and effective for creating monochromatic artworks or shades in artworks.

Allows graphic artists and designers to explore and use their creativity as they can try various approaches to use small dots of only one-color ink to create the illusion of different shades.

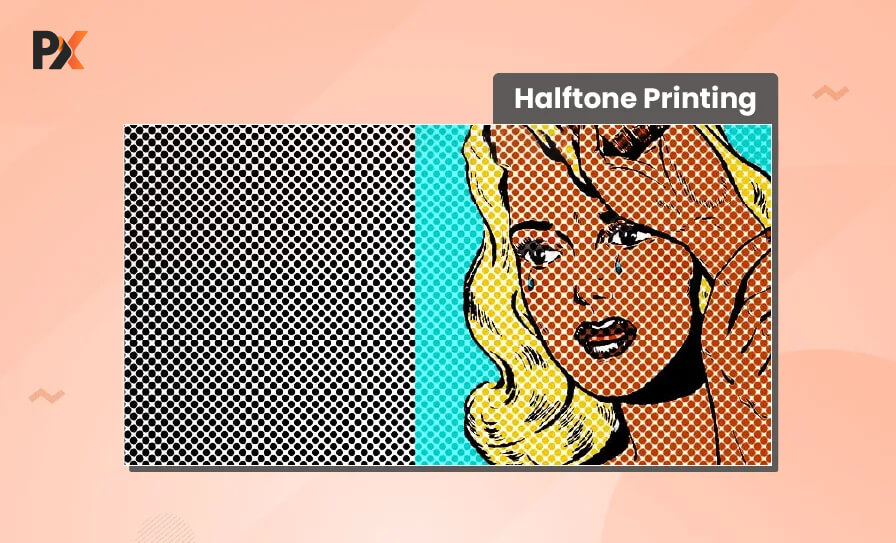

3. Grayscale Printing

Grayscale printing uses shades of gray ranging from black to white. Screen printers catch these shades by:

– Either increasing or reflecting white light, or

– Decreasing or absorbing (not reflecting) the reflection of black light.

Though it sounds like the black and white technique, it is not. The difference is that while the black and white technique uses true black and true white to define the images, the grayscale technique doesn’t. Rather, it actually pulls out the RGB or CMY color scales only but in shades of gray.

After ensuring the design or image is in good resolution, you can change the images to grayscale and these images have a shade to represent a color from RGB or CMY even though it gets converted to grays from black and white.

The reason behind this representation is that the pixels have brightness measurable enough to signify its shade.

Or we can say that gray shades lie somewhere between or in a spectrum of zero brightness (black) and all brightness (white). Every shade in the image (after conversion to grayscale) lies somewhere in this bracket, depending on the brightness level of each pixel.

Benefits

– Cost-effective as there is no expense in additional colors.

– High-quality images in light and dark shades of gray at affordable prices.

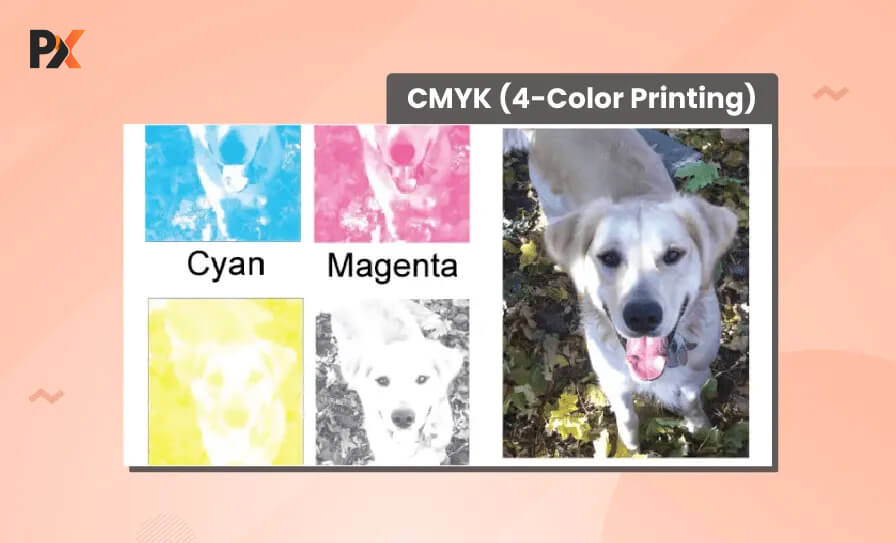

4. CMYK (4-Color Printing)

The CMYK printing involves the four basic colors – cyan, magenta, yellow, and key, or black. If you are looking for screen printing methods that help you create multi-colored prints at an affordable cost, this method can work well.

An important stage of this process is the coinciding of the four colors with the black key plate. This crucial stage allows for detailing to facilitate proper viewing of the image as the key plate lets different shades and contrasts form the image.

Benefits

– Fewer colors help control the overall expenses.

– More suitable for light colored, white clothing materials.

Prints are equivalent to images that use more than 4 colors in terms of quality.

Do you want to get the right price for your Artwork?

Learn all the hows and whys before setting a certain price for your Artwork!

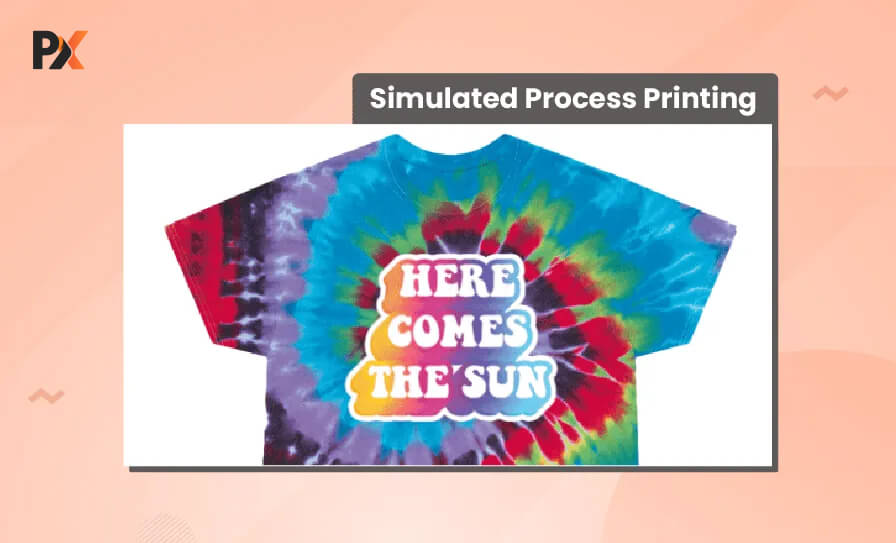

5. Simulated Process Printing

There are multiple types of screen printing to print designs – own creation, photograph, specific phrase, or name on apparel, wood piece, or anything else. Out of many, Simulated Process Printing is one of the most popular screen printing methods.

Especially it is popular for photo prints because it allows for halftones of colors to encompass a design.

This screen printing method emphasizes the use of halftone ink colors to capture the colors of the original design. Also called the sim process, it can be useful for both lighter and darker shades of material.

You can separate the design or image. This helps them identify colors. You can also make the image as creative or as simple as required.

Spot colors are used but blended together with halftones and gradients to maximize the visual. This makes the scope for a vibrant image or design on the article of clothing.

Benefits:

– The final image printed is bold, realistic, and detailed.

– Useful for both darker and lighter shades – hence versatile and popular

6. Duotone Printing

Duotone printing is the screen printing method that uses a combination of two halftones for the same image printed with 2 colors.

In other words, there is a black halftone printed in black ink and another second halftone printed in color ink like warm brown or any other. The warm brown halftone combines with the black halftone to create a duotone print which has the color hue of the warm brown halftone. It is quite similar to a sepia-toned print in photography.

Benefits

– Useful for light materials and apparels

– Imparts a sophisticated and artsy look to the final print.

Now that you are well-acquainted with the major types of screen printing, here are 3 major factors to consider before you start a screen printing business.

Factors to Consider before Picking a Screen Printing Method

Number of colors

A bright, colorful design is always eye-catching and appealing. But at the same time, considering the number of colors to use in design is equally important. The more the colors are, the higher the printing costs go. Therefore, managing colors for a particular artwork order is crucial – especially if you own a small business with a few customers in the initial phase.

An idea that can help you cut down on printing costs without compromising quality is minimizing shades of a particular color and sticking just to primary colors. This way, you can have multiple colors in your design without having to shell out a huge amount for each design order.

Another pro tip you can use is this – Let your customers pick from a range of pricing options decided as per the number and shades they want to be used for printing. Displaying this list of pricing options won’t only enhance transparency but also reduce the unnecessary back and forth and your efforts in explaining the prices you charge for a particular order to a minimum.

As a result, order placement will become easier and faster – and offer a seamless experience to customers. And you can stay on top of customer satisfaction.

Printing Area

Proper positioning of designs is a point worth considering.

For instance, if you have to print a company logo, printing it on an area like a sleeve or ribcage can cost more – the reason being difficulty in printing on such areas. While on the other hand, if you have to print the same logo on the front or back, it might cost much less.

Quality and Quantity of Apparel

The apparel must be fit for the screen method printing you want to use on it. Generally, screen printing is more cost-effective for bulk orders – as the printing cost per piece goes down.

In general, natural fabric is an ideal choice for screen printers.

As a thumb of rule, here are the most suitable fabrics for screen printing.

– 100% cotton – As it is prone to shrinkage and wrinkles and saves extra effort in printing designs on ‘tough’ locations.

– 100% polyester – Not as breathable as cotton, but strong, durable, and long-lasting. Resistant to shrinking, wrinkles, and color fading over time.

Sometimes, a 50-50 blend of cotton and polyester can also work well at times.

Ready to Start Screen Printing Business?

Screen printing is an age-old printing technique for custom artwork and has always been a popular choice for bulk orders. By understanding all types of screen printing, comparing them, and analyzing your requirements, you are now ready to pick the right screen printing method for your business.

Further, you can also manage pricing options for the range of colors customers select by using good color management software. Our PrintXpand tool can help with color pricing management and streamlining screen printing orders.

Turn your printing business into a profitable one by picking up a wide range of printing processes. Analyze the above processes and pick the right method for your business. Or check out how product designing works and what parameters you need to focus on for your product design business to skyrocket.

All product and company names are trademarks™, registered®, or copyright© trademarks of their respective holders. The use of them does not imply any affiliation with or endorsement by them.