Summary

From receiving the order to shipping it, there’s a lot of action going on in the core process. It takes systematic management to ensure your printing cycle is streamlined and working efficiently. This seems like a challenging task, but it is actually easy if you use the right tools and strategies for it.

Here, inventory management software is the right tool to streamline your printing process without any effort. It can lend you a helping hand in solving numerous challenges you might be facing regularly. In this blog, I have mentioned some of the major challenges that can affect your sales and revenue drastically and how Print ERP’s Inventory Management Software can solve them for you.

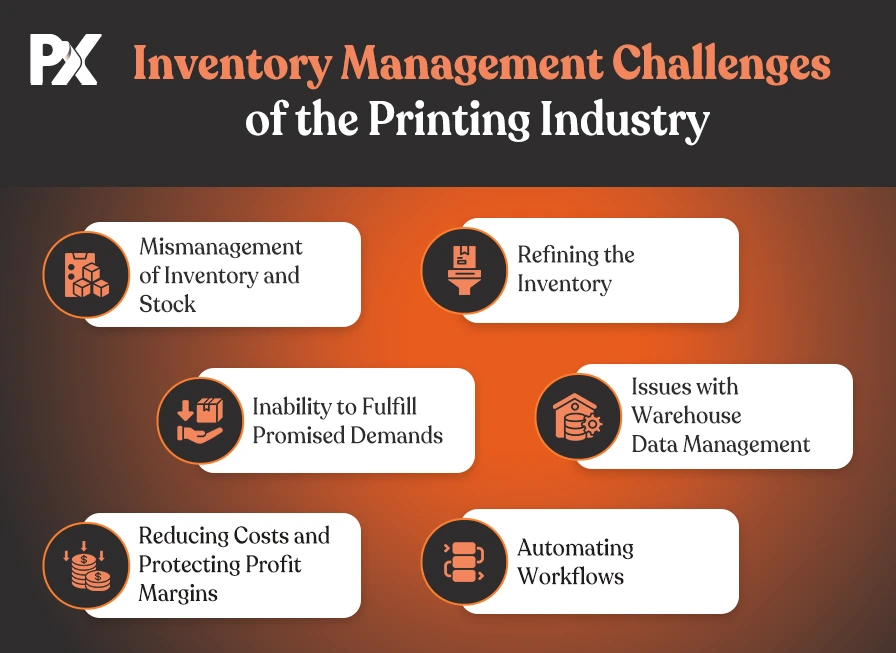

6 Inventory Challenges of the Printing Industry

Challenge #1: Mismanagement of Inventory and Stock

Managing stock is the trickiest responsibility. If the manager does not have an accurate account of the inventory, then there can be late deliveries and loss of loyal customers, as well as loss of money. There can be times when you take an order but have no raw material to work with, which will lead to late delivery.

If the deliveries are late, it may cause the customer some loss, and it would form a wrong impression of your company. Suppose the manager has counted the stocks wrong and informed you that the stock needs to be purchased, but actually the stock is already enough so it doesn’t need to be purchased. This leads to a loss of money because buying unnecessary stock can get damaged.

Solution:

To avoid mismanagement of your stock, you need to shift to software in order to remove human errors. An automated system like Print ERP provides seamless inventory management. It is an end-to-end print business manager software. It partners with you to optimize your business operations with automated workflow and other dynamic features like Vendor Association and Raising Purchase Orders, you can streamline inventory.

Vendor Management: This feature lets you save the vendor details for each product. You can save the database of your vendors in your software. This way you don’t have to waste time looking for details about vendors while raising a purchase order.

Raising Purchase Orders: With this feature, you can directly raise a purchase order when required. As you already have the vendor details saved for placing your orders, this feature will directly place the order for the required quantity of that particular material. It will save time and provide convenience.

In the search for an inventory manager with such features, we have found you the perfect match!

Challenge #2: Refining the Inventory

You must have often faced this challenge that once the ordered inventory arrives and you check the stock, you find that there are some defective materials. So that way, your actual count should only be the number of useful materials. To sort out the defective ones from the operable ones takes time and effort, both if done manually. Plus, there are chances of human errors. Do not fret; there’s always a solution.

Solution:

To ensure that your count is up-to-date with only the useful stock, you can use the inventory management system. With features like Rule Based Inventory Management, you can automate the stock counting process. You will have two options to choose from; either you can allow its original quantity as the inventory stock count or you can automate the checking process and allow only the usable ones as the inventory stock count, To even further increas your overall productivity you would also need artificial technology that is often used in smart offices.

Let us understand this with an example:

Let’s say you ordered 500 plain white t-shirts. Now you can automate the received items directly to be your stock number. After this, the software will show 500 plain white t-shirts as your final stock count.

The second option is to automate the sorting process, where the software automatically sorts the defective items and displays only the operable items. So, if there are 100 defective t-shirts, then the software will display only 400 t-shirts to deliver.

Challenge #3: Inability to Fulfill Promised Demands

Having loyal customers is not just a matter of luck. It takes effort like on-time deliveries, proper packaging, discounts, and always being ready to cater to their demands. The one thing that needs to be constant here is their trust in your company. For that, you need to make your company the one that never breaks promises, and it’s not an easy task.

Providing on-time delivery can get hampered by many factors like change in weather, unavailability of the delivery partner, and unavailability of ordered items. You can have all of them in control, let’s see how:

Solution:

First, let’s talk about the things that are in your control. When the customer places their order, you promise them the date and time to fulfill their order and to complete that order on the promised dates is your duty. You can use Print ERP Software that alerts you whenever your stock goes below the minimum required quantity. This alert will help you to place the purchase order and will also save you from making impossible promises. This way, you can have transparency with your customers by adding the stock numbers on the eStore, like ‘only 12 items left in stock.

Challenge #4: Issues with Warehouse Data Management

Managing warehouse data is a complex process, especially when you have multiple warehouses. Managing inventory of all the warehouses and all the locations in the warehouses is a task that needs to be done error-free. You should not compromise on this backend process because it will reflect on the overall service quality of your company.

You might be in a situation where you are unaware of the stock of some warehouses, and you order more stock for the warehouse where it is needed. But, you already have the same material stocked in mass quantity in one of your other warehouses where it is not required.

So, rather than purchasing new productions, you can just transfer the materials from one warehouse where it is not much in use to the warehouse where it is needed. But this can only happen when you know the status of all the warehouses and their internal locations.

Solution:

With a solution like Print ERP Software, you can manage one warehouse with multiple locations and multiple warehouses with multiple locations easily. Its Internal Stock Transfer feature lets you have visibility of stock in all the locations to make the stock shifting easy for you.

With this feature, you can have a look at all the stock in all the locations of all your warehouses, and it saves you unnecessary expenses. You can simply transfer the unrequired stock from one warehouse to the other warehouse where it is in demand. The transportation cost will be much less than buying materials.

Challenge #5: Reducing Costs and Protecting Profit Margins

The print industry often faces the uphill battle of managing high overhead costs, which can eat into profit margins. Expenses related to equipment, materials, labor, and technology can be substantial, making it challenging to maintain healthy profitability.

Solution:

Leveraging advanced print technology can significantly reduce material wastage and boost production efficiency, while efficient resource allocation through software solutions like Print ERP helps identify areas for improvement.

Negotiating with suppliers for better pricing terms and bulk discounts can further optimize expenses. Process automation offers the advantage of reducing labor costs and minimizing errors.

Additionally, effective inventory management aids in controlling material costs and minimizing excess stock. To get better visibility into your financials, get an accounting tool that will simplify and automate everything from transaction tracking and invoicing to bank reconciliation and tax management. It will also help you stay on top of your numbers, reduce manual errors, and make better budgeting decisions.

By adopting these cost-effective strategies and embracing technology, print businesses can not only protect their profit margins but also ensure long-term financial sustainability.

Challenge #6: Automating Workflows

Manually managing day-to-day printing operations slows down the whole production process. From ordering to tracking inventory to suppliers and reporting, errors are bound to happen if everything relies on human input. Not only does this eat into your team’s time, but it also affects order accuracy, turnaround time, and, ultimately, customer satisfaction.

Even small tasks like raising a purchase order or transferring stock between warehouses become repetitive and time-consuming without automation. As your business grows, this naturally becomes a major bottleneck.

Solution:

The key to streamlining your printing operations is to automate routine tasks and workflows. Print ERP has smart workflow automation features that reduces manual intervention and eliminates repetitive tasks.

With a print ERP built with a focus on inventory management and automation, you can:

- Auto-generate purchase orders when the stock hits a minimum level

- Update inventory levels efficiently in real time across all warehouses

- Keep up with hassle-free stock checks and get alerts on low inventory

- Manage internal stock transfers and approvals

- Set rules and triggers for vendor communication

Put simply, this frees up your team to focus on more strategic, revenue-generating activities. And the best part? Automation improves accuracy, reduces delays, and a smoother operational flow from order to delivery.

Strategies to Nail Inventory Management in Your Printing Business

Inventory issues can snowball quickly if not managed properly. To avoid those common pitfalls and improve your day-to-day operations, here are some practical strategies you can start implementing today.

Invest in a Printing Inventory Management Software

If managing inventory feels like a constant struggle, it might be time to bring in some help. The right inventory management software can take a huge load off your shoulders—saving you time, reducing errors, and making day-to-day tasks a whole lot smoother.

It’s easy to lose track of small things like inks or materials. To stay organized and meet customer demands on time, this software will be your go-to partner.

Plan Smartly

Planning is an inseparable part of any goal. You need to plan the inventory in order to manage it efficiently. You will need to plan when and where the stocks will be needed. You need to track the availability and requirements of materials in different warehouses. Many issues can come out of nowhere for which you might be unprepared for like:

- Sudden sales spike

- Scarcity of space in your warehouse

- Wrong predictions

- Manufacturer running out of the product you need urgently

But with proper planning, all these problems can be solved. You need to figure out your risks and always have a plan B. For example, if your ink supplier is out of the required ink’s stock, then you must contact another manufacturer that can provide you with your required shade of ink in required quantity with the required quality.

In case of a sudden sales spike, you need to have your warehouses stocked to fulfill the customer’s demands, or you should have other options to provide them with. If your prediction goes wrong, then you should have a plan of where you will use the remaining stock and save it from getting wasted.

Regular Real-time Updates

Regular inventory check-ups are crucial. You can surely rely on the inventory management software for its warehouse management capacities. Still, you, as the owner of the company, need to check the warehouse status to plan well.

You must double-check if you have set the notification for the software to alert you when the stock goes below the minimum required quantity. Here, choose software that provides you with real-time updates and has a mobile-friendly interface to be updated whenever and wherever you want.

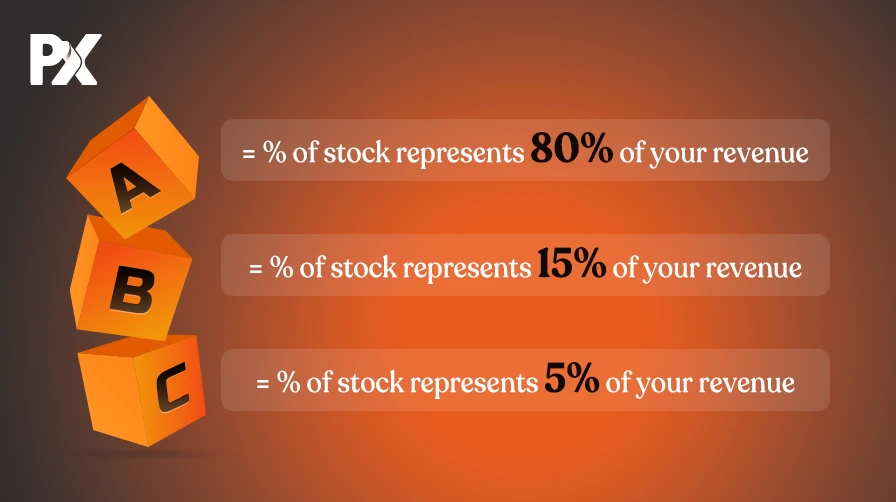

ABC analysis

ABC analysis is the simplest way to know the important reports and stock usages. It will give you a clear view of which products are selling more and which need to be improved. This analysis needs to be calculated on a percentage basis:

Clearly, your A stock represents the most profitable products because they sell the most. So, you can make sure you have these products in your warehouse to not miss out on any sudden sales spike.

B stock represents the moderate-selling products, but you need to have this stocked in some quantity as it can rise in demand anytime.

And C stock is slow-moving, or we can say dead stock. You can sell this stock at a discount to free up your inventory space and save yourself from major losses like dumping all that stock for nothing if damaged.

Forecast

Forecasting is the toughest thing to do because no one can know what the future holds, so calculated prediction is the best way to be ready for future challenges. Listed below are a few things that can help you in projecting a close future:

- Keep a constant watch on the trends in the market

- Analyze when your products are selling the most

- Have some guaranteed sales from a few contracts and subscriptions

- Plan promotions by using trendy strategies relevant to your printing niche

Wrapping Up

With these solutions and strategies, you can productively manage your printing industry. Ensure that the software you choose has the following features:

- Vendor Association

- Raising Purchase Orders

- Warehouse Management

- Internal Stock transfer

- Rule-Based Inventory Management

These features will help you to make the process of inventory management hassle-free. It will give you daily necessary reports and insights that are important for you to plan further things. Also, you need to make sure that the ERP solution you opt for is compatible with your eStore and multiple devices.

End Your Search for an Ideal Inventory Manager with PrintXpand

Challenges in the printing industry are not limited to inventory and warehouse. There are multiple challenges that block the way for sales. PrintXpand’s Print ERP can help you to overcome all the challenges for you to make way for more revenue.

Investing in this dynamic tool is like having a personal manager for multiple tasks and departments of your printing store. From backend management to frontend visibility, this tool can help you in all the desired ways to make your printing store efficient and management smooth.

PrintXpand’s provides you with this magic software that has all the necessary features. Take a demo now

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.