What comes to your mind when you hear printing?

I can imagine vibrant colors, fine fabrics, and aesthetic designs.

One method of creating all sorts of fabrics, textiles, and products is Ink + screen (mesh stencil) = screen printing. Different industries carry out this process of pressing ink through a stenciled mesh screen to create a printed design.

While the industrial definition calls it a technique, I would call it an art because the end-product is so visually appealing and no less than an artwork.

If you are reading this, I assume you are here because:

A. You are in the screen-printing space

B. You have taken a leap from manual to automatic printing or planning to do so.

If you belong to the second category, then I applaud your decision of upgrading to automatic screen printing. You have chosen profits, shorter production and turnaround time, and lower labor costs. As per studies, textile printing machine markets will be reaching $13,988 million by 2025. Therefore, you have an ocean of opportunities ahead with a printing capacity of 2,139prints/hour with automatic screen printing.

After deciding to upgrade to an automatic machine, the next step is the quest for the right machine. To make your task easier, here’s a list of top automatic print screen machines that will help you carry out your print business like a pro.

A. M&R Global

If you want customized yet innovative features that deliver exceptional speed and control then M&R’s Stryker is for you.

M&R is a popular manufacturer of digital and screen-printing equipment. They are dedicated to providing customers with the most advanced, durable, and user-friendly equipment available. For over 30 years M&R has helped countless screen printers realize their dreams by supplying them with innovative screens and digital printing products that stand the test of time. Its numerous patented innovations made it a receipt of Product-of-the-Year Awards in 2017.

Let’s dive in!

1. Stryker Automatic Oval Screen-Printing Machine

Stryker’s specialty is the standard oval design which takes up less floor space than comparable carousel automatic screen-printing presses. This results in more efficient use of the available production area.

The best thing about Stryker is that it includes innovative standard features like the Maintenance Minder system that alerts operators when scheduled maintenance is due. Its user-friendly features like park mode speed setup and teardown times.

Specifications:

| Print format sizes | Available in three sizes- 6080 (24″ x 33″)70100 (27.5″ x 39″) and 80110 (31.5″ x 43.5″) |

| Stations | Expandable from 10 to 52 stations |

| Printing capacity | 80×110 model can print up to 132 x 110 cm (52″ x 43.5″) in alternating printheads |

Features:

– Modular design allows custom configurations

– Built of heavy-duty steel and premium components

– Large touchscreen display uses icon-based commands for ease of operation

– Automatic palette preheat mode with built-in pallet temperature sensor

– Electronically adjustable ink retrieval system

– Tool-free calibrated front & rear stroke length adjustment to maximize printing speed

Warranty: Two-year or 2,000,000-cycle limited warranty

Here’s another automatic machine by M&R:

2. Sportsman EX Automatic Screen-Printing Press

Sportsman EXpress is a benchmark in mid-range automatic screen-printing presses that combines quality components, leading class craftsmanship, and high-speed production all at an amazingly affordable price. This machine features electric printheads, servo-driven indexers, multiple print-stroke capabilities, and a new color touchscreen interface, and simplifying screen printing. It also includes onboard self-diagnostics and real-time production data display.

Specifications:

| Color | 6 to 12-color models |

| Maximum image area | 41 x 46 cm (16” x 18”), 51 x 51 cm (20″ x 20″) or 51 x 71 cm (20” x 28”) |

| Printing capacity | 80×110 model can print up to 132 x 110 cm (52″ x 43.5″) in alternating printheads |

| Standard pallet size | 41 x 56 cm (16″ x 22″), 56 x 63 cm (22″ x 25″) or 56 x 76 cm (22” x 30”)/td> |

Features:

– Standard front and rear locking micro-registration

– Standard pneumatic squeegee/flood bar and frame locks

– High-resolution touchscreen control panel

B. Ryonet

If you wish durability and versatility in your printing process then Ryonet’s ROQ evolution is a good option.

Ryonet is an all in one place for screen printing supplies, equipment, and education you need. They provide quality materials to help any screen printer, large business, hobPrintXpandsts, or a small business owner.

3. ROQ Oval Evolution Automatic Screen-Printing Process

The real strength of ROQ lies in finding solutions– modifications to products, creating or innovating a new engineering solution, or any other type of need. This model by allowing large printing areas gives an impeccable performance. It presents a reduced performance due to its robustness.

Specifications:

| Colors | Available from 1 to infinite colors |

| TouchScreen | 15” polychromatic touch panel |

| Print Area | 20″ x 28″ (XL) | 28″ x 39″ (2XL) | 31″ x 43″ (3XL) | 35″ x 51′” (4XL) |

Features:

– Honey-comb aluminum pallets

– AC electric printheads that have individual command function

– Printheads with pneumatic high-lift position

– Individual print and flood controls for speed, height, angle and stroke length

– AC servo-motor indexing system

– AC servo-motor rotation system

– Rear command for a double production

– Micro registration screen system with Vernier scale

Warranty: 3 Years

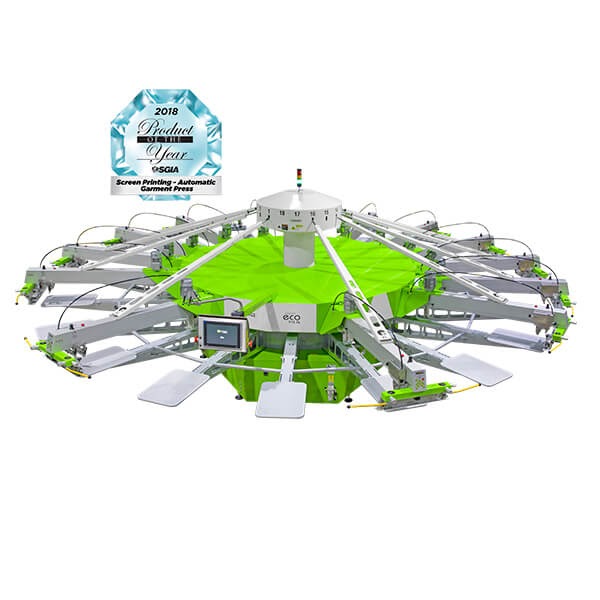

4. ROQprint ECO

It won Product of the Year awards at SGIA 2018 in Screen Printing – Automatic Garment Press. The ROQprint Eco is built with top of the line materials and its biggest focus is to create and deliver a top-quality machine that requires minimum maintenance.

Specifications:

| Colors | 1-18 colors |

| Pallet | Minimum of 12 pallets up to a maximum of 20 pallets |

| TouchScreen | Polychromatic LCD touch screen (10”) |

| Print Area | 450 mm x 550mm up to a maximum of 800mm x 1100mm. |

Features:

– Aluminum honeycomb pallets;

– Squeegees with electric movement with ac variator;

– Independent control panel

– AC servo-motor rotation system

– Placement of the Flash Cure

Warranty: 3 Years

Free Demo: Sell t-shirts without worrying about designs, printing, or inventory.

C. TAS America

The vision of TAS America is to provide quality alternatives to higher-priced new equipment. TAS introduced the industry’s first 16 colors automatic screen-printing machine with smart electric heads back in 1998. Years of experience have made TAS a reliable source of automatic screen-printing solutions.

5. HAWK HX Series Screen Printing Machine

HAWK HX Series is an intermediate size machine, with a generous print area of up to 50cm x 63cm (20” x 25”) and is available in up to 16 colors upon request. The Hawk series consists of eight different models.

Specifications:

| Colors | 20 |

| Stations | 22 |

| Print area | 508MM X 635mm (20″ X 25″) |

| Diameter | 6400 |

| weight | 5700kg |

Features:

– Electric indexer and print heads

– Central Off Contact

– Roto Print Program

– Calibrated Individual Off-Contact

– Multi-Functional Foot Switch Pedal

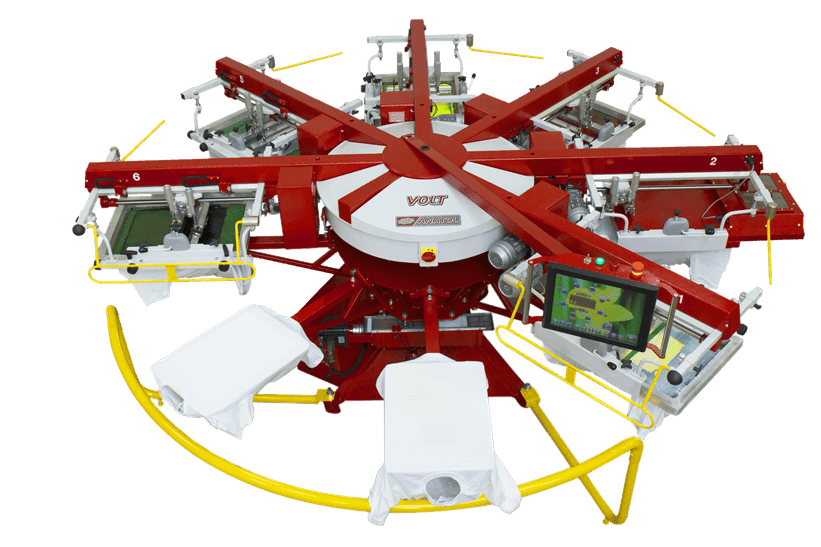

D. Anatol

If you want to change the way you work by adding smart technology that surpasses traditional screen-printing equipment then Antol’s VOLT is for you.

Anatol Equipment is a leading screen-printing equipment manufacturer for textile printing and more. Its printing machines are helping printers produce high-quality work with speed, efficiency, and reliability. Their tailored equipment helps increase your production speed and volume.

6. Automatic VOLT

The VOLT by Anatol is a professional-grade electric automatic screen-printing machine. It gives you the speed, power and reliability of a screen-printing press without the issues of a compressor or chiller. The energy-efficient VOLT uses servo-driven indexers to ensure zero downtime caused by leaks.

Specifications:

| Print Area | 15” x 16” up to 20” x 28” |

| Configurations | 6 stations/2 colors up to 20 stations/18 colors |

| Touchscreen | 15” touchscreen with Aries 2 operating system |

Features:

– View real-time print count (dozen) and speed (pcs/hr.)

– Heavy-duty rolled steel frame to support smooth, high-speed production cycles

– Laser alignment system for quick and easy apparel alignment

– Proven servo technology

– AC electric print heads

– Industry’s best safety bars at each print head

– Anatol offers the benefits of VOLTs with four different models as well!

Warranty: Three Years

Also Read: Top 6 Type of Screen Printing Methods

E. Workhorse Products

Workhouse Products’ automatic screen-printing press lineup are known for their practical and easy to use products. If you are looking for the best entry-level screen-printing press, their freedom express series will be suitable.

Workhorse Products is a dominant player in the textile screen printing industry for decades. They engineer and design products and accessories that ensure quality, value, service, longevity, and performance. Let’s discover three automatic printing presses by Workhouse.

7. The Freedom Express Series

It is the premier entry-level machine. This fully pneumatic press allows you a seamless transition from manual to automatic printing.

Specifications:

| Color Options | 6 |

| Print area | 15″ x 15″ |

| Electric | 110V, 50-60Hz, 3amps |

| Diameter | 10’ |

Features:

– Intuitive software with functions like Sample Print Mode, Missed Shirt Feature, and Orbital Mode.

– Independent print & flood speed

– Super-responsive front & rear micro registration

– Advanced chopper system

– All-access control panel

– Flashback compatible

8. The Cutlass Series

This equipment delivers a perfect balance of affordability and performance and helps you with the everyday rigors of your print shop.

Specifications:

| Color Options | 6,8 |

| Print area | 20″ x 20″ |

| 6 color – Electric & air | 220v, 5amps | 110psi, 22cfm |

| 8 color- Electric & air | 220v, 6amps | 110psi, 24cfm |

| 6 color dimension | 12’6″ |

| 8 color dimension | 14′ |

Features:

– Touch screen interface

– Air Print Heads & Electric Indexing

– Patent-pending AC/electric indexer

– Super-responsive front & rear micro registration

– Advanced chopper system that improves stroke length

– Patent flashback system

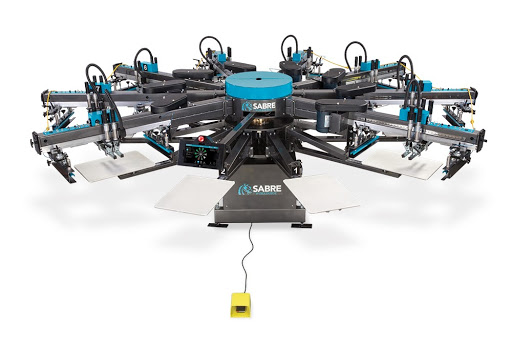

9. The Sabre Series

The comprehensive and feature-rich Sabre automatic screen-printing machine is the best that Workhorse has to offer.

Specifications:

| Color Options | 6-12 |

| Print area | 20″ x 20″ |

| Overall diameter | 12’6″, 14′, 15’6″, 18′ |

Features:

– Touch screen display, stroke functions, self-diagnostics, and machine updates.

– Zero-delay double indexing, multiple station indexing, AC/electric indexer

– Plug N Go flash capabilities

– AC/electric driven printheads with independent print/flood speed controls on each.

F. Brown Manufacturing Group

If your small business requires a solution that is innovative yet affordable then Automatic Machines by Brown Manufacturing can help you.

Brown Manufacturing Group is a company led by innovators and problem solvers who are always eager to provide prompt and accurate customer service. Their team is always in the research and development mind-set therefore you can expect innovative ideas and new products frequently. The machines by Brown Manufacturing Group give a long-term reliable performance, have innovative useful features, and are affordable for smaller businesses.

10. ElectraPrint Automatic Textile Printer- AP810

This machine is quick to run, easier to maintain, and affordable to operate. As compared to common air-driven systems, the end-product by this machine is consistent. It does not require an air compressor, air chiller, regulators, or airlines.

Specifications:

| Color Options | 8 |

| Stations | 10 |

| Standard power | 120V, 20A, 1 |

| Power-up option | 240V, 20A, 1 |

| Screen size | 23″ x 31″ |

| Platen size | 16″ x 24 |

| Dimension | 144.00″ x 144.00″ x 60.00″ |

| Weight | 2800.00lbs |

Features:

– Direct drive micro registration system

– Independent flood bar and squeegee/squeegee pressure

– Independent head off-contact adjustment

– Front screen loading

– The hardened steel registration system

– Electric drive and lift

– Electric print heads

G. ASPE

If you are looking for an automatic print machine that makes printing small images on garments easy; then check out the RapidTag Series of ASPE.

ASPE is a manufacturing company that specializes in making products for the garment and promotional product industries. The work with an aim to serve their clients efficiently and flawlessly with the innovative technology

RapidTag Series

With RapidTag, you can now print all your labels (sleeve prints, on-the-pocket prints, nape of neck prints, bags, socks, gloves, napkins, etc.) quickly. The best part about these RAPIDTAG screen printing equipment is that they are highly customizable to serve your different needs. The cost-effective RapidTag series offers five different models. Here, we will discuss the most popular machine.

11. LP4 XL – Four Color Automatic Screen-Printing Machine

Allowing printing for four-color images, the LP-4XL is their most powerful model. It is perfect for sleeve prints.

Specifications:

| Stations | 6x |

| Print heads | 4x |

| Standard Pallet Size | 13.5″ Wide x 16 ” Long (34.29 cm x 40.64 cm) |

| Standard Frame Size | 16 x 20 (40.64 cm x 50.8 cm) |

| Diameter | 90 inches (7.5 Feet) |

Features:

– Pneumatic screen lock

– Stroke adjustment

– Squeegee angle adjustment

– Motion sensor

– High-Density Flash Cure Units

– Color Touch Screen

– Hoodie arms

– Servo Indexer

– Adjustable Stroke and flood speed

Watch the video and find out for yourself how compact and perfect the machine is!

With this, we complete our list of best automatic screen-printing machines available in the market.

Now the next obvious question that comes to your mind is which one should I purchase?

Stitching from manual to automatic machine is a major decision and you would want something that saves you time, provides accurate results, and caters to every requirement of your business.

To help you with this, below are a few points to keep in mind.

– Press Configuration: Every machine has different configurations based on colors and stations. Choose the machine depending on your print type (simple or complex), customer demand, capabilities, and designs. Quick Tip: choosing a machine of an upgraded level will enhance your job.

– Machine Size: Size depends on the space available. If you have a wider space, you can pick 14 colors to 8 color automatic machines.

– Electric power system: If your business is home-based, a one-phase electric system is enough. But if you are running a large business then you can go for a three-phase power system.

– Before finalizing, focus on support equipment. Check if the dryer is large enough for extra production, exposure unit is of the right size.

– The number of colors and stations depends on the workload. This means that more colors will take less time to complete the job.

– As automatic machines have pneumatics, you will require airlines. They will make maintenance and troubleshooting effortless.

– If you are a beginner or require a machine for household use 1 color screen printing is enough. But if you think you will use the machine for years to come then go for 4 or 8 colors.

– A quality compressor is important. If your compressor breaks down then your entire business might suffer.

Over to you!

I hope this short list helps you make the right choice. Picking the best automatic screen-printing machine will have a direct impact on the success of your business. Therefore, be very careful about what you choose. Once you finish this step you are all set to print some cool t-shirts all by yourself!

Want to Grow your Print Business? See how you can do that with our product design tool!

All product and company names are trademarks™, registered®, or copyright© trademarks of their respective holders. The use of them does not imply any affiliation with or endorsement by them.

![11 Best Automatic Screen Printing Machines of 2020 [Specifications & Tips] 11 Best Automatic Screen Printing Machines of 2020 [Specifications & Tips]](https://www.printxpand.com/wp-content/uploads/2021/04/top-11-automatic-screen-printing-machines.png)